About Welding

Welding is a fabrication technique where materials, typically metals, are joined through the melting and fusion process, employing heat and often a filler material to create a robust and enduring bond.

2 common areas of welding are:

- Traditional welding (TIG, MAG, MIG processes)

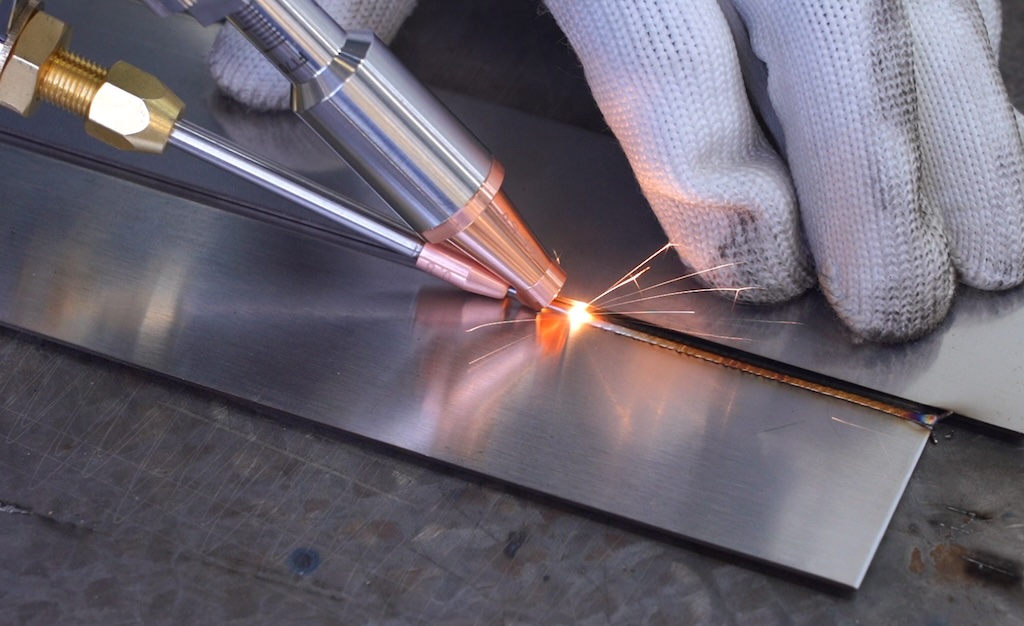

- Stud welding: attachment metal studs, threaded or unthreaded, to a workpiece, commonly steel or aluminum, creating a strong and reliable connection.

Technical features

Standard Welding

Welding processes available:

- TIG

- MAG

- MIG

6 welding units:

- 4x 1200 x 2400 mm

- 2x 1000 x 2000 mm

Stud Welding

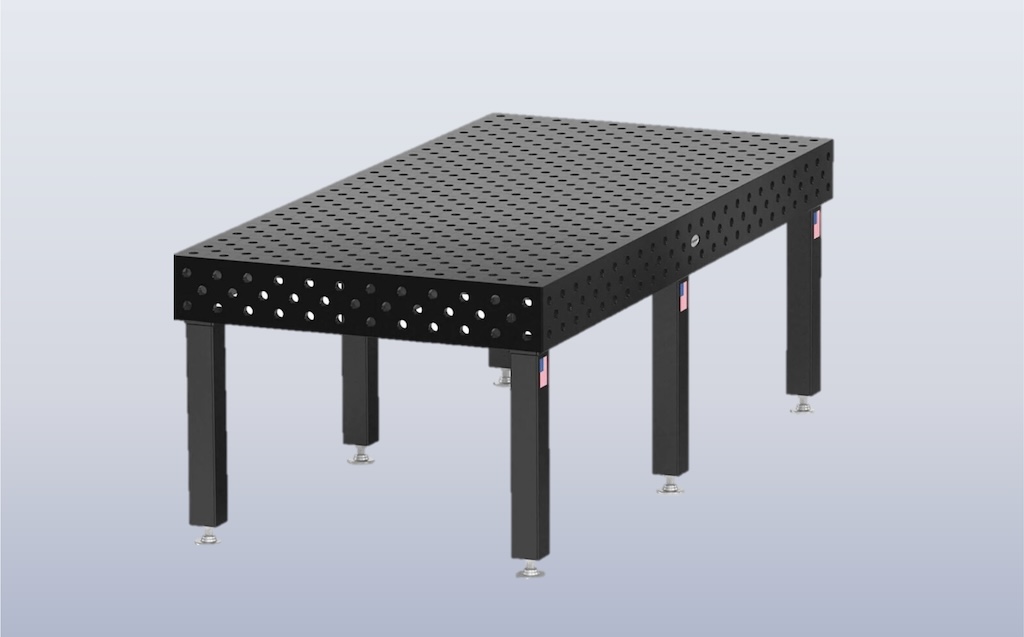

Soyer KTS-2550 CNC:

- Clamping surface = 3100 x 1600 mm

- Working area (X/Y) = 1400 x 2550 mm

- Loading capacity of table: 100 kg

- Accuracy: +/- 0.2 mm

Soyer KTS-550 CNC:

- Clamping surface = 940 x 725 mm

- Working area (X/Y) = 490 x 485 mm

- Loading capacity of table: 100 kg

- Accuracy: +/- 0.15 mm

Need our services? Feel free to contact us for a free consultation.

Our capabilities

Equipped with advanced welding technologies, we excel in fusing metal components with accuracy and strength.

Our skilled team of welders brings proficiency to the creation of robust and durable welded assemblies for various industries.

Whether tackling prototypes or large-scale projects, our welding services are tailored to meet a diverse range of requirements.