About Punching

Punching is a metalworking process utilizing a punch press to deform or cut holes in materials by applying force through a punch and die set, ensuring accurate and efficient production of perforated sheets, patterns, or openings in metalwork with cost-effective and speedy results.

Technical features

Possible materials: Steel, chrome steel, aluminum, copper and brass

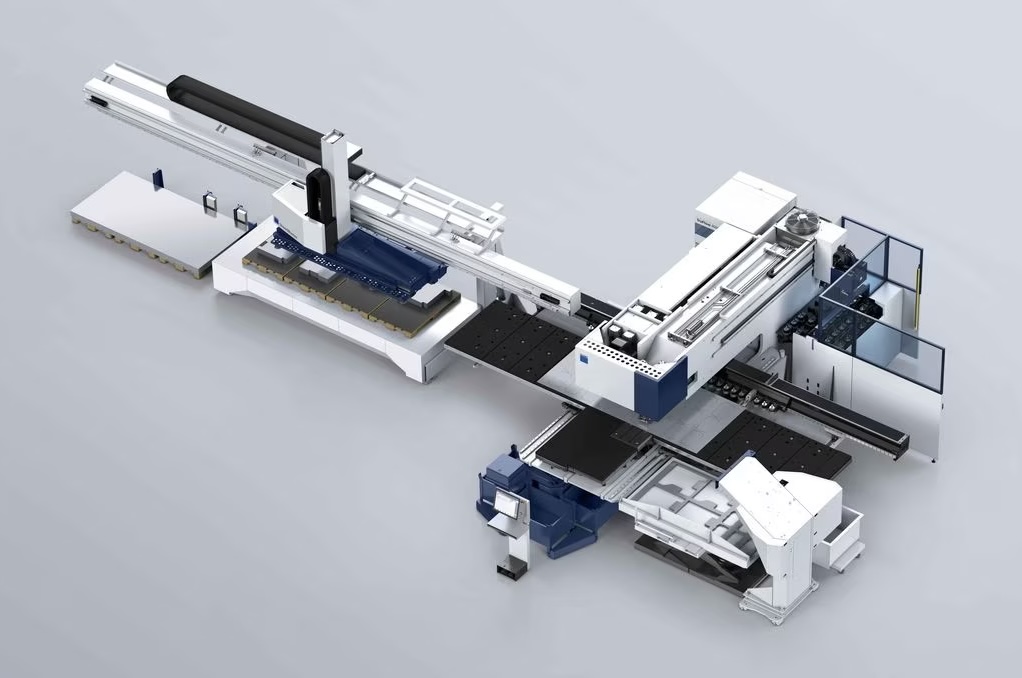

Working area of operating laser: 3050 x 1550 mm

Max. sheet thickness:

- sheet steel 8 mm

- chrome steel 8 mm

- aluminum 6 mm

Tolerance: +/- 100 μm

Max. punching force: 220 kN

Max. laser power: 4000 W

Automation: Full automatic loading and unloading

Need our services? Feel free to contact us for a free consultation.

Our capabilities

The TruMatic 7000 brings together the advantages of punch and laser processing in a particularly cost-efficient way. The high-end punch laser machine meets high demands in regards to part quality, productivity, and flexibility. With the active die, we can produce scratch-free parts and profit from the greatest level of flexibility when forming.